our approach aimed at maximizing productivity & efficiency.

Founder, SH Turnstile Factory.

modern ways of manufacturing products.

Modern manufacturing is a blend of advanced technologies and streamlined methodologies. Key concepts and techniques include:

- Automation and Robotics: Robots and automated systems handle repetitive, high-precision tasks, minimizing human intervention, increasing efficiency, and lowering labor costs. This is often part of Industry 4.0, or “smart manufacturing,” which integrates information technology with operational technology.

- Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM): CAD software is used to design products digitally, while CAM systems guide computer-controlled machines (like CNC machines) to manufacture the parts with high precision and consistency.

- Precision Machining: CNC (Computer Numerical Control) machines, along with other advanced tools like laser cutters, are used to form and shape materials with extreme accuracy, reducing waste and ensuring high-quality components.

- Additive Manufacturing (3D Printing): While not used for all components, 3D printing is valuable for creating prototypes, specialized parts, and complex geometries with minimal waste.

- Joining and Assembly: Techniques like laser welding, automated fastening, and robotic assembly are used to join components with strength and precision.

- Advanced Materials and Coatings: Manufacturers use materials like durable stainless steel (e.g., 304 or 316) for its weather resistance and strength. Modern coating processes like powder coating provide a durable, rust-resistant, and aesthetically pleasing finish.

- Lean Manufacturing: A methodology focused on maximizing efficiency by reducing waste in all aspects of the production process, from materials to time.

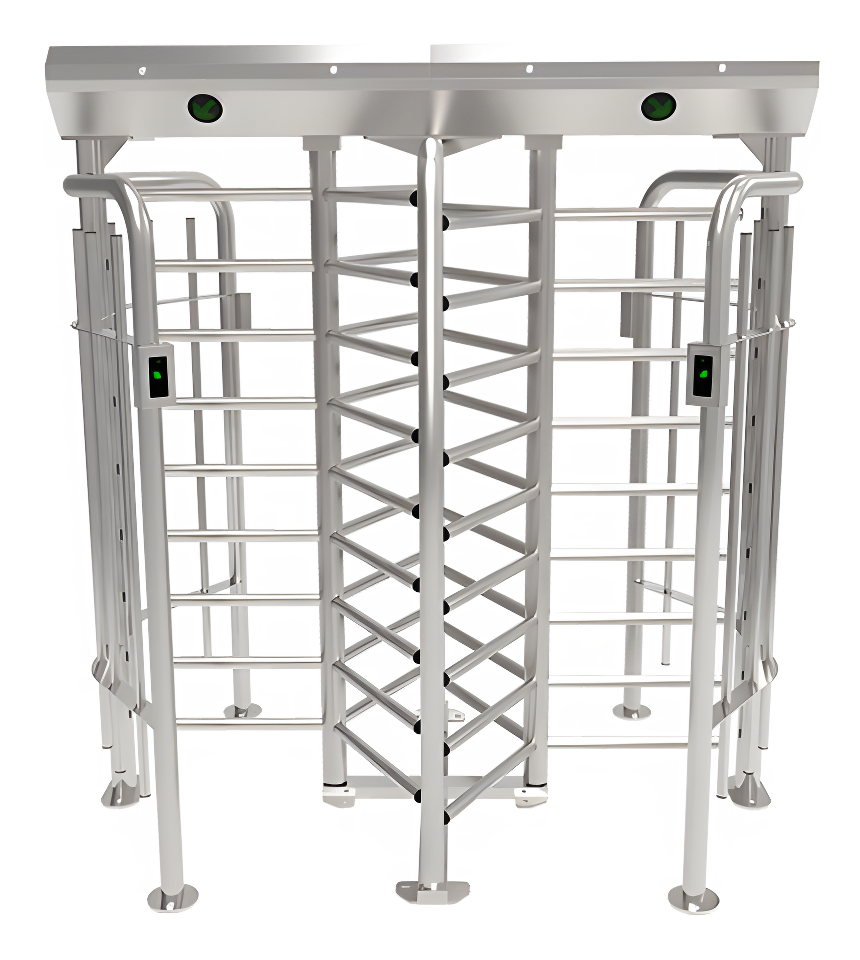

Manufacturing a Full Height Turnstile

A full height turnstile is a robust, high-security access control device designed to prevent unauthorized entry by creating a complete barrier from floor to ceiling. Its manufacturing process is built on the same modern principles as other turnstiles but with a focus on producing larger, more durable, and tamper-proof components.

1. Design and Prototyping (CAD & 3D Printing): The process begins with CAD (Computer-Aided Design) software, where engineers create detailed digital models of the entire structure, including the full-height rotating drum, robust frame, and security locking mechanism. This allows for virtual stress testing and optimization of the design for maximum security and durability. Due to the scale of the product, 3D printing may be used for rapid prototyping of complex internal components or locking mechanisms to ensure perfect functionality before full-scale production.

2. Component Manufacturing (Precision Machining & Forming): The primary components of a full height turnstile are fabricated using modern, high-precision techniques suited for large-scale, heavy-duty parts:

- Frame and Housing: The sturdy frame and housing, typically made from heavy-gauge steel, are cut and shaped using powerful CNC laser cutting machines and automated press brakes. This ensures a perfect fit and a strong, unyielding structure. The parts are then welded together, often using robotic welding systems for consistent, high-strength seams.

- Rotating Drum and Arms: The large rotating drum and its internal arms are the core of the security barrier. These are manufactured from strong, durable steel. The arms are precisely cut and shaped to prevent climbing, while the central mechanism is machined using CNC milling and turning to create a flawless, heavy-duty bearing and drive system capable of withstanding constant use and abuse.

- Mechanism: The electromechanical heart of the turnstile, which controls the rotation and locking, is a high-torque system. Its gears, shafts, and locking components are processed by CNC machine tools to ensure extreme accuracy, high-impact resistance, and a long operational life.

3. Integration of Electronics and Control Systems: The full height turnstile’s intelligent features are derived from its advanced electronic control system, a critical step for its security function:

- PCBs (Printed Circuit Boards): The sophisticated control boards are manufactured on automated assembly lines, with robotic systems placing and soldering components with precision to ensure reliability.

- Sensors and Logic: The system relies on sensors (e.g., infrared sensors) to detect a person’s presence and direction. The central control system processes these signals along with commands from integrated access control devices (card readers, biometric scanners, etc.). The wiring and integration are designed for maximum security, often with components housed in secure, tamper-proof compartments.

- Software: The turnstile’s firmware and operational software, which include complex logic for managing entry/exit, anti-passback functions, and fail-safe or fail-secure settings, are programmed and loaded onto the control board.

4. Assembly and Joining (Robotics & Manual Assembly): The final assembly process is a meticulous combination of automation and skilled craftsmanship:

- The heavy rotating drum and the locking mechanism are carefully mounted within the main frame.

- The electronic control board, motor, and sensors are wired and securely integrated into the chassis.

- Due to the size and weight of the components, automated systems and cranes are often used for lifting and positioning, while skilled technicians handle the delicate wiring and calibration of the electronic and mechanical systems.

5. Finishing and Quality Control: The final steps are crucial for ensuring the product’s durability, security, and long-term performance:

- Coating: The steel components are often galvanized and then finished with a heavy-duty powder coating. This involves electrostatically applying a powder, which is then cured under high heat to form an extremely hard, chip-resistant, and corrosion-proof finish, essential for both indoor and outdoor installations.

- Testing: Every full height turnstile undergoes a rigorous, multi-point testing process. This includes thousands of automated test cycles to check the locking mechanism’s reliability, the motor’s durability, the responsiveness of the sensors, and the strength of the overall structure. This “no-fault” testing ensures the turnstile meets its demanding security and operational lifespan requirements.

Focus on Heavy-Duty Security and Durability

The manufacturing process is centered on creating a robust, high-security barrier.

- Robust Materials & Construction: The process uses heavy-gauge steel for the frame and rotating drum. Robotic welding ensures high-strength seams, and components are designed to be tamper-proof and resistant to force.

- High-Torque Mechanism: The core mechanism is built with a high-torque motor and heavy-duty components processed by CNC machines. This ensures the turnstile can withstand constant use and resist attempts to force it open or break it.

Advanced Electronics for Secure Access Management

A full height turnstile’s functionality relies on advanced electronics for its security features.

- Anti-Passback and Fail-Safe Logic: The control system is programmed with sophisticated software that includes anti-passback functions, which prevent a user from passing their credential back to another person. It also has specific fail-safe or fail-secure settings for emergencies.

- Secure Integration: All electronic components, including control boards, sensors, and wiring, are integrated into secure, tamper-proof compartments within the heavy-duty frame, protecting the system’s “brain” from physical attack.

service related FAQ’s

Yes, SH turnstiles can withstand temperatures from -40 to +60°C.

We accept bank transfers (T/T), as well as PayPal, MoneyGram, and Western Union payments.

For a single lane, you’ll need two single-core turnstiles. For two lanes, you’ll need two single-core turnstiles and one double-core turnstile. And for three lanes, you’ll need two single-core and two double-core turnstiles.

Tripod, full-height, and optical swing gates can be placed outside with no roofing. On the other hand, optical flap turnstiles need to be covered, as they can malfunction if they come in contact with water.

By default, the gates will automatically open if the power goes out. However, you can disable this function if you prefer it that way.